-

Industrial Waste Shredder

-

Double Shaft Shredder

-

Plastic Waste Shredder

-

Rag Cutting Machine

-

Single Shaft Shredder

-

Plastic Film Shredder

-

Solid Waste Shredder

-

Cardboard Box Shredder

-

Drum Shredder Machine

-

Bottle Shredder Machine

-

Scrap Metal Shredder

-

Waste Wood Shredder

-

E Waste Shredder

-

Animal Shredder Machine

-

Waste Tire Shredder

-

Four Shaft Shredder

-

Shredder Spare Parts

-

Mr. EndritMachines running good. Fantastic autually Thank you so much for your help and supporting

Mr. EndritMachines running good. Fantastic autually Thank you so much for your help and supporting -

Mr. Paulo DuarteMachine running ok. and we are very satisfied with after-sale service.

Mr. Paulo DuarteMachine running ok. and we are very satisfied with after-sale service. -

Mr. CersorMachine good. Just I hope the return visit can be every month instead of every two weeks 'cause we have no problem ask

Mr. CersorMachine good. Just I hope the return visit can be every month instead of every two weeks 'cause we have no problem ask

Waste Cans Iron Recycling Machine High Efficiency With Rotary Moving Blades

| Place of Origin | CN |

|---|---|

| Brand Name | Joful |

| Certification | CE |

| Model Number | S-600/700/800/1000/1200...T-400/600/800/1000/1200/1500/2000 F-600/800/1000/1200/1600... |

| Minimum Order Quantity | 1 Set |

| Price | Negotiable |

| Packaging Details | Film , EPE Foam , Export Wooden Box |

| Delivery Time | 7 - 45 Working Days |

| Payment Terms | T/T , L/C |

| Supply Ability | 35 sets per month |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Blade Material | Sicr Cris H13 Ld SKDII D2 Customizable | Color | Blue Grey Red Customizable |

|---|---|---|---|

| Machine Size | Base On Different Crush Demand | Package | Film , EPE Foam , Export Wooden Box |

| Capacity | Customizable | Product Name | Scrap Drum Shredder, Waste Cans Shredder,shredding Machine For Waste Metal Cans / Aluminum Cans,cans Shredding |

| Application | Drum / Cans, Other Hollow Containers , Wood,E Waste ... | Warranty | 12 Months & Life-long In Time Free Technical Support |

| High Light | steel drum shredder,medical waste shredder |

||

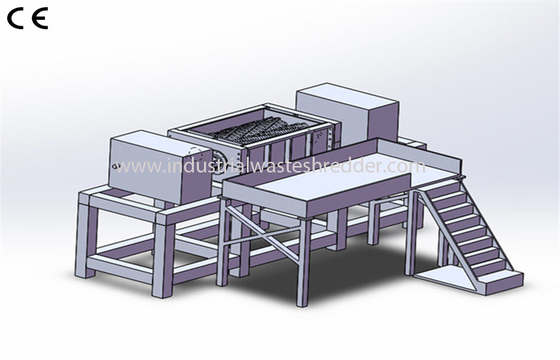

Industrial Iron Drum Shredder Machine , Industrial Waste Cans Shredder Machine , Plastic box shredder

Introduction of Iron Drum Shredder , waste cans shredder

For each shredder machine, the key point part is shredding chamber,it is consist of rotary moving blades,stationary blades,spacer,shaft and chamber wall. The design of blade,claws on blade and space between shafts are decided by the materials which need to be shredded.Therefore,to produce the most suitable machine we have to learn detailed request of shred request from clients. So please kindly introduce which material you want to shred,what's your capacity demand as well as final output size request before asking for quotation.

The Joful drum / Cans Shredder is normally used as pre shredder for coarse shredding . The machine with different sizes and different configuration levels for shredding different sizes Cans. The claw number, diameter and the thickness of the blade is decided to the crushing material and the discharging size , the machine capacity is decided to the different crushing material and the discharging size. Therefore,we mainly sell customized shredder machines . Standard models is not good choice for clients,as one size machine can not fit all !

Advantages of Waste iron Drum / Cans Shredder

| 1. Use imported high-quality alloy steel blade,with high strength,good toughness,not easy to break . |

| 2. Rotary blades can use integral blades or assemble blades, blades structure can be divided into single claw blades,double claw blades and multi-claw blades,those are depends on your shred demands |

| 3. Shaft adopt a special material processed by CNC machine, with high strength,good toughness,so can guarantee no out of shape problem after long time using |

| 4. The whole shredding chamber was processed by CNC machine,with high precision,easy dis-assembly,repair & maintenance. |

| 5. Shredding chamber adopt large thickness,high strength,wear resistance of steel.Very load-bearing and stable during working |

Waste iron Drum / Cans Shredder machine photos display

![]()

Quick details

1. Lead time - 48 working days

2. Payment Term - 30% advanced payment once upon signing the contract,70% balance payment before delivery.

3. Machine Installation

- a. Almost whole set machine delivery out, very simple for clients to install by themselves and we also offer installation drawing

- b. If necessary we also support abroad installation

4. Our guarantee period is 12 months. Within the guarantee period the broken parts (excluding quick-wear parts) can be exchanged with our new parts if it is not caused by human factors. And technicians are available for solving big problems overseas(this situation never happened ). Beyond the guarantee period the broken parts dispatched are charged at cost price.